Normally Closed Automatic Tool Sensor Gauge and similar items

Free Shipping

Normally Closed Automatic Tool Sensor Gauge CNC Mach3 Z Axis Probe Setter, Black

$161.82 CAD

View full item details »

Shipping options

Seller handling time is 2 business days Details

No shipping price specified to CA

Ships from

United States

Return policy

Full refund available within 30 days

Purchase protection

Payment options

PayPal accepted

PayPal Credit accepted

Venmo accepted

PayPal, MasterCard, Visa, Discover, and American Express accepted

Maestro accepted

Amazon Pay accepted

Nuvei accepted

View full item details »

Shipping options

Seller handling time is 2 business days Details

No shipping price specified to CA

Ships from

United States

Return policy

Full refund available within 30 days

Purchase protection

Payment options

PayPal accepted

PayPal Credit accepted

Venmo accepted

PayPal, MasterCard, Visa, Discover, and American Express accepted

Maestro accepted

Amazon Pay accepted

Nuvei accepted

Item traits

| Category: | |

|---|---|

| Quantity Available: |

Only one in stock, order soon |

| Condition: |

New |

| Model: |

BLACK |

| Brand: |

Does not apply |

| Item model number: |

BLACK |

| Material: |

Alloy Steel |

| Country of Origin: |

China |

| Range: |

0.005 meters |

| Measurement Accuracy: |

0.001 |

| Package Dimensions: |

6.06 x 4.09 x 2.91 inches; 1.08 Pounds |

| Type: |

Does not apply |

| UPC: |

7445023572555 |

Listing details

| Shipping discount: |

Seller pays shipping for this item. |

|---|---|

| Posted for sale: |

May 18 |

| Item number: |

1747649288 |

Item description

Store

New Arrivals

Add to Favorite

View Feedback

Contact

Normally Closed Automatic Tool Sensor Gauge CNC Mach3 Z Axis Probe Setter, Black

Description

Item model number

BLACK

Material

Alloy Steel

Country of Origin

China

Range

0.005 meters

Measurement Accuracy

0.001

Model

BLACK

Package Dimensions

6.06 x 4.09 x 2.91 inches; 1.08 Pounds

?MAIN FUNCTIONS?Tool sensor gauge is a special tool setting instrument for the engraving machine and CNC equipments. The output of it is received by the numerical control system and then the tool length setting, tool wear detection and tool breakage are detected by the program control.

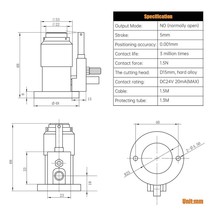

?MULTIPLE ADVANTAGES?High precision: 0.001mm; High sealing performance: waterproof, oil resistant, dustproof; Stable performance; Overtravel alarm: prevent damage accidents

?HIGH QUALITY?Housing Material: 4S grinding grade material; Tube: 1 meters minimum bending radius R25;Cable: 2 meters oil resistant 4-core; contact material:super hard alloy,IP67 waterproof

?WIDE APPLICATIONS?Normally closed design, and equipped with cable, can be used with most CNC equipments.

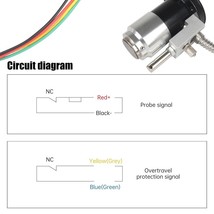

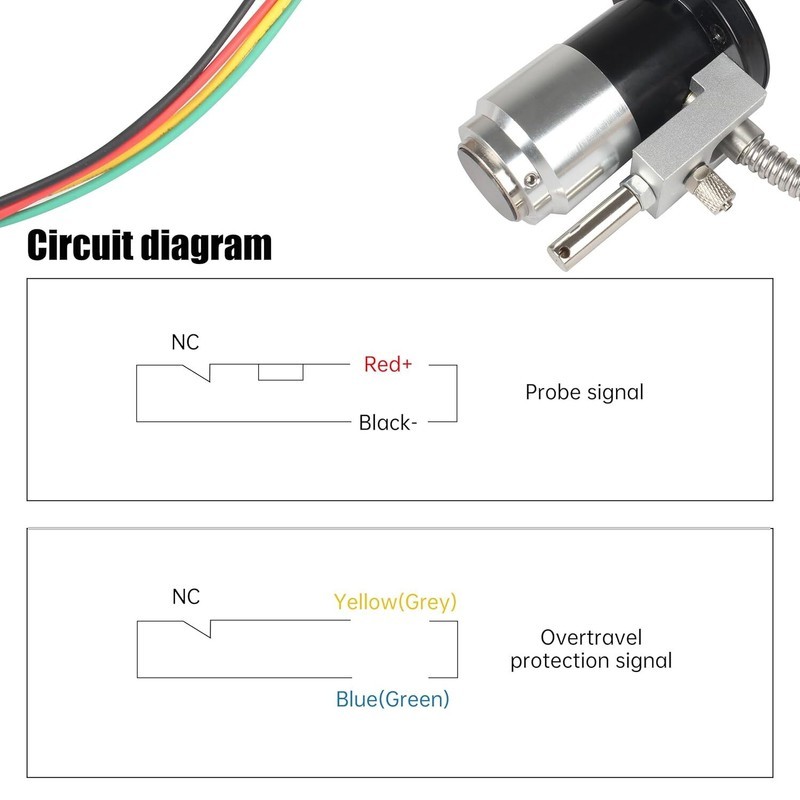

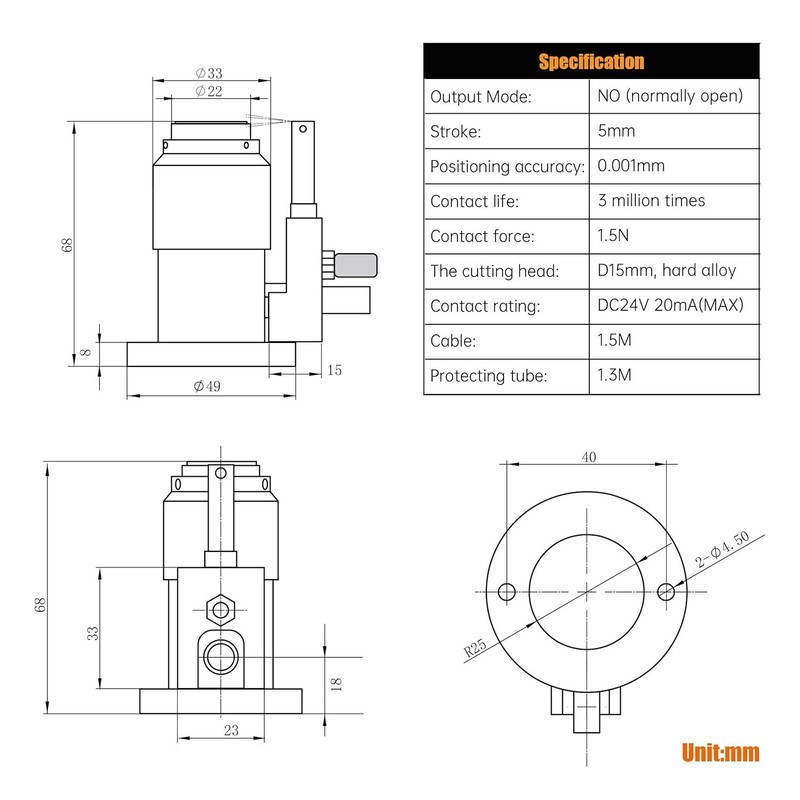

?SPECIFICATION PARAMETERS?The normally closed 4-wire high-precision tool setting setter with a stroke of 5mm. The positioning accuracy is 0.001mm, the contact life is up to 3 million times, the contact force is 1.5N, and the contact rating: DC24V 20mA.

Product Description

Package List: 1PC Tool Setting Gauge + 1PC Accessory

Specifications

Output Mode NC (normally closed) Stroke 5mm Positioning accuracy 0.001mm (speed: 20-200mm/min) Contact life 3 million times Contact force 1.5N

The cutting head D15mm, hard alloy Contact rating DC24V 20mA(MAX), recommend (10mA) resistive load Cable 1.5M Materials Hard alloy, the design is exquisite and the installation is simple.

Note: 1. Please control the probe speed at 50-200mm/min. 2. Use ambient temperature range 0 C-80 C. 3.Please control the voltage at DC0-24V and the current below 20mA.

CNC Automatic Tool Sensor Gauge Changer

A. Mach3 Normally Closed

The tool setting instrument is suitable for the engraving machine machining center machine. The output signal of the tool setting instrument is received by the numerical control system and then the tool length setting, tool wear detection and tool breakage are detected by the program control.

B. Mechanical Installation :

1. Try to install on the workbench where there is less iron filings and less splashing water. 2.Must be installed vertically, to ensure that the bottom is flat to avoid causing large precision errors. 3.Be sure to power off before installation. After the wiring is completed, place the tool setting tool in another place on the tool holder. After the tool signal is normal, fix the correct position.

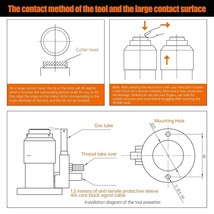

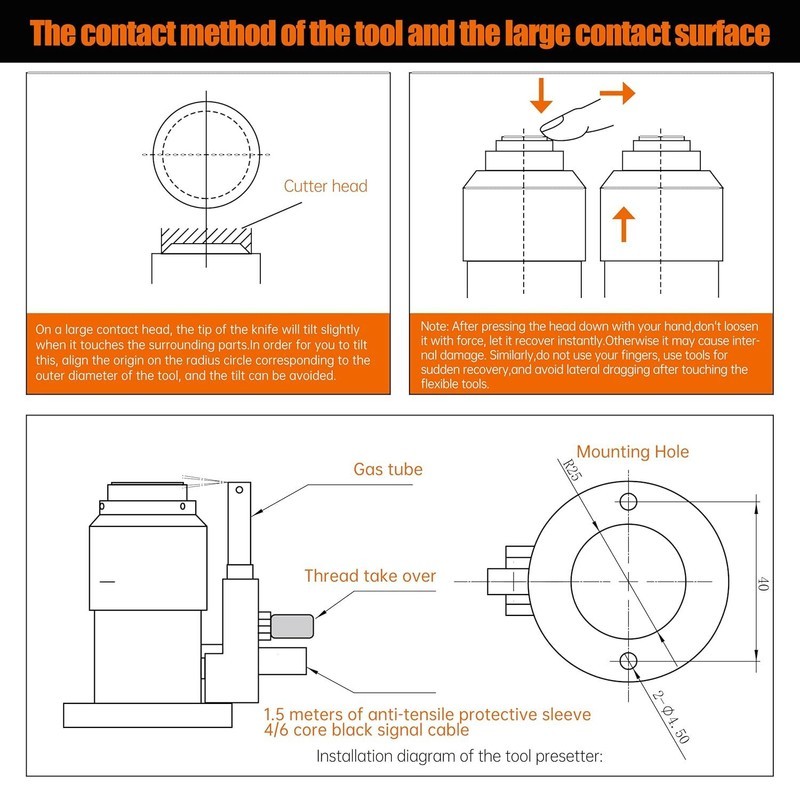

C. Tool Contactt Method:

1.When installing, use the tip of the tool to face the contactt and press down directly. 2.The stroke of the tool holder must be taken into accountt. Do not press excessive force, which may cause damage to the knife and tool. 3.The speed of aligning the sword is related to the response speed of the appliance on the mechanical side, so be careful not to exceed the specified speed when setting. It is recommended to set the parameters according to the manual in order to ensure the accuracy of the tool setting. 4.The repeatability of 50-200mm/min is 0.001mm (when the response speed of the mechanical control system is within 0.5msec), but when the drill diameter is within 0.5mm, use low-speed contact.

D. The contactt method of the tool and the large contact surface:

1.On a large contactt head, there is a slight tilt when the tool touches the surrounding area. In order to compensate for this inclination, the original point is aligned on the radius of the corresponding outer diameter of the tool, and the inclination can be avoided 2. Note: After pressing the contactt down by hand, do not suddenly loosen it and let it recover instantly. Failure to do so may result in internal damage. Similarly, without using your fingers, use the tool to suddenly recover, or use the tool to touch and then drag horizontally to avoid.

Detail Display

Long service life

Super hard alloy material, wear-resistant and long service life.

Air Vent Hose

Blow off the chips and coolant that are resurrected on the contactt surface and the tool.

The radius ofair tube passage is 2 mm or more in diameter.

Air intake Hose

Blow off the required hose length and cut it in the direction of the axis lag. (There must be a margin for the length)

How to Arrange Air intake Hose

Insert the cap nut into the hose.

The hose must be inserted into the innermost part to avoid air leakage and pipe slippage

Tighten the cap nut by hand.

Advantage

A. Dustproof and Waterproof

Dustproof and waterproof structure, it still has good durability under the condition of coolant and iron filings flying.

B. No need a built-in amplifier

1. No deviation caused by the temperature of the tool position and the fluctuation of the power supply voltage.

2. It can be directly input to NC and program (PLC).

C. Hard Alloy Materials

The housing material is 4S grinding grade material; The bottom magnet design can be directly connected to the machine and firmly adsorbed to the body; The contactt material is super hard alloy

D. Over-travel Alarm Signal

The tool setter will send out an alarm signal in time when it is over-travel to avoid other troubles caused by equipment operation.

Mach3 Normally Closed

The tool setting instrument is suitable for the engraving machine machining center machine. The output signal of the tool setting instrument is received by the numerical control system and then the tool length setting, tool wear detection and tool breakage are detected by the program control.

ABOUT US

We offer the best prices around on high quality products. Our E-store includes media such as books, movies, music and games while offering electronics, toys, sporting apparel, clothing, tools, general home, garden items and more.

SHIPPING

We are always working hard to ensure your package arrives as soon as possible. Please understand that some factors like weather, high postal traffic, and the performance of shipping companies are outside of our control.

RETURNS

We offer a 30-Day Return Policy on items which you are not completely satisfied with. You have the option for a full-refund or an exchange of the item.

PAYMENT

We accept PayPal.

CONTACT US

This page content is yet to come

Please ad us to your favorite seller and visit again later

Thank You

CUSTOMER SATISFACTION

We try our very best to make sure every customer is completely satisfied. If there's a problem, message us! We're happy to help.

Loading

This item has been added to your cart

Normally Closed Automatic Tool Sensor Gauge CNC Mach3 Z Axis Probe Setter, Black added to cart.

Only one available in stock

Normally Closed Automatic Tool Sensor Gauge CNC Mach3 Z Axis Probe Setter, Black added to cart.

Only one available in stock

View Cart or continue shopping.

Please wait while we finish adding this item to your cart.

Please wait while we finish adding this item to your cart.

Get an item reminder

We'll email you a link to your item now and follow up with a single reminder (if you'd like one). That's it! No spam, no hassle.

Already have an account?

Log in and add this item to your wish list.