Rendered at 20:06:35 05/20/25

Free Shipping

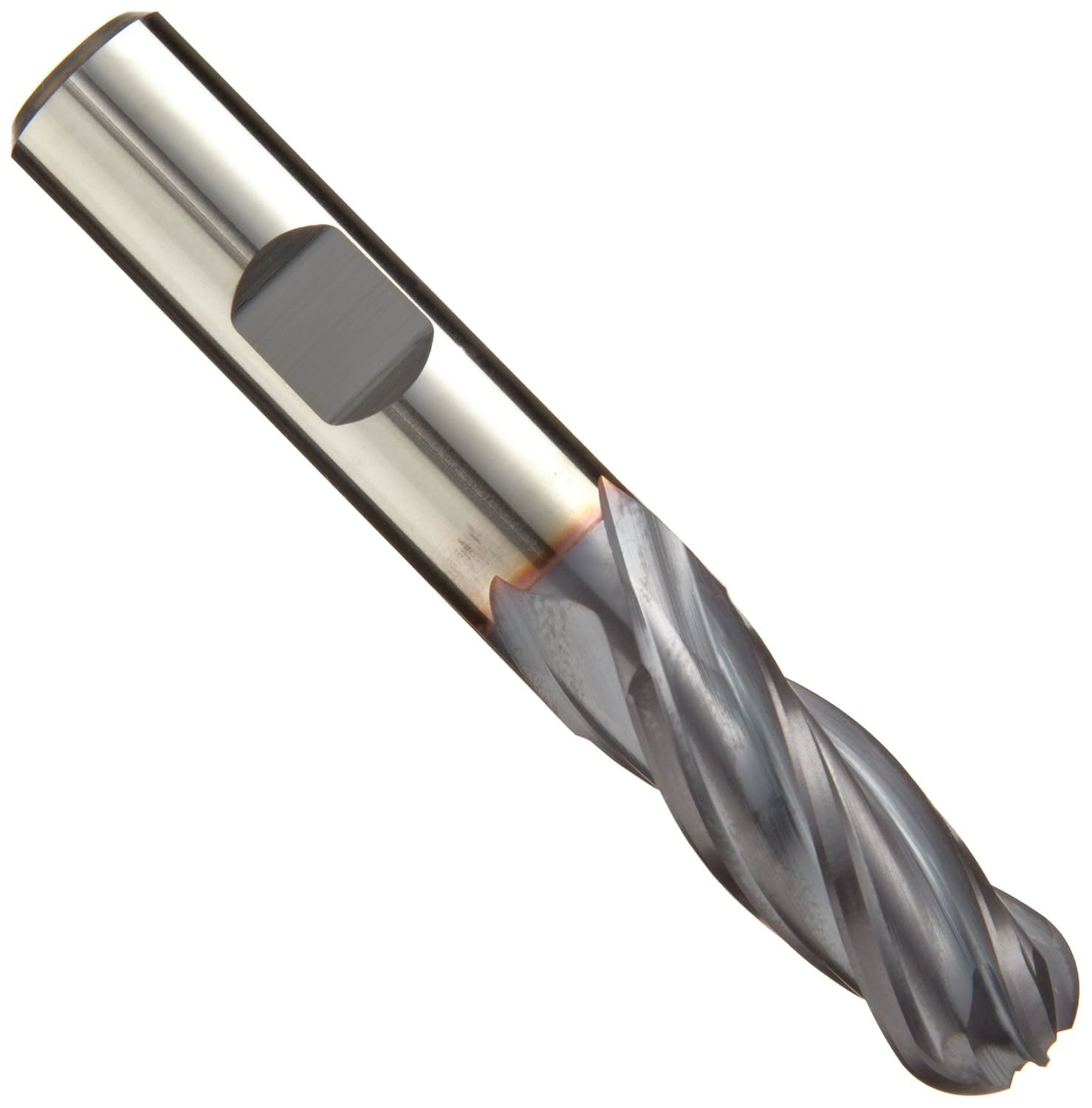

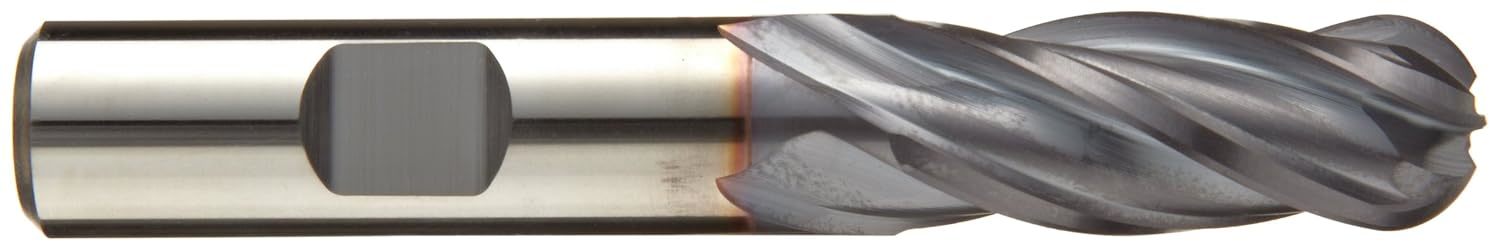

Niagara Cutter N67345 Cobalt Steel Ball Nose End Mill, Weldon Shank, Ticn

$101.72 CAD

Ships from

United States

Shipping options

Seller handling time is 3 business days Details

No shipping price specified to CA

Ships from

United States

Offer policy

OBO - Seller accepts offers on this item.

Details

Return policy

Full refund available within 30 days

Details

Purchase protection

Payment options

PayPal accepted

PayPal Credit accepted

Venmo accepted

PayPal, MasterCard, Visa, Discover, and American Express accepted

Maestro accepted

Amazon Pay accepted

Nuvei accepted

Shipping options

Seller handling time is 3 business days Details

No shipping price specified to CA

Ships from

United States

Offer policy

OBO - Seller accepts offers on this item.

Details

Return policy

Full refund available within 30 days

Details

Purchase protection

Payment options

PayPal accepted

PayPal Credit accepted

Venmo accepted

PayPal, MasterCard, Visa, Discover, and American Express accepted

Maestro accepted

Amazon Pay accepted

Nuvei accepted

Item traits

| Category: | |

|---|---|

| Quantity Available: |

3 in stock |

| Condition: |

New |

| Brand: |

Niagara Cutter |

| UPC: |

698036673451 |

| Package Dimensions: |

3.3 X 0.7 X 0.6 Inches; 2.4 Ounces |

Listing details

| Seller policies: | |

|---|---|

| Shipping discount: |

Seller pays shipping for this item. |

| Posted for sale: |

More than a week ago |

| Item number: |

1706377436 |

Item description

Niagara Cutter N67345 Cobalt Steel Ball Nose End Mill, Weldon Shank, Ticn

Product Details

The Niagara Cutter SPB540 TiCN-coated cobalt steel ball nose end mill has a 30-degree helix angle to shape contoured surfaces on a wide range of materials, including high-temperature alloys. The number of flutes varies; fewer flutes provide better chip-carrying capacity, while more flutes produce a finer finish. The TiCN coating lubricates the end mill for high-temperature stability, and provides more hardness and abrasion resistance than the TiN coating. The cobalt steel substrate can be run at faster speeds and stays sharp longer than high-speed steel tools, while offering greater resistance to heat and abrasion. The 30-degree helix angle offers general-purpose machining. It balances lower angles? strong cutting edge for difficult-to-machine materials with higher angles? increased cutting action. The ball end creates contoured surfaces where sharp edges are not required. The center-cutting design has cutting teeth at the end of the tool. It can be fed straight into the workpiece like a drill bit for plunge cutting, and used for applications such as slotting and profiling. Cutting diameter tolerance is +0.001? to -0.000?. The end mill has a Weldon shank. End mills are designed to remove material and create multi-dimensional shapes and profiles. They have cutting edges along the outside diameter and flutes that remove chips from the cutting area and allow cooling fluids to enter. If heat is not reduced effectively, the tool?s cutting edges will dull and additional material buildup can occur. The number of flutes can range from two to eight. Two-flute designs offer the most efficient chip removal, but more flutes provide a smoother finish. The shank is the end of the tool held in place by a tool holder or machine. Center-cutting end mills can create three-dimensional shapes and profiles, and make plunge cuts similar to a drill bit. Non-center-cutting end mills are for applications such as peripheral milling and finishing, but cannot make plunge cuts. Niagara Cutter has been designing and manufacturing precision cutting tools since 1954. Specializing in end mills, cutting mills, and saws, the company is based in New York and manufactures its tools at facilities in Pennsylvania and Massachusetts. This allows the company control over production, from substrate to coating, which is essential for customers in a variety of industries, especially aerospace and automotive.

4 Flute design for creating finer finishes and creating a higher metal removal rate General purpose end mill for working on all types of materials and high temperature alloys Cobalt steel tools are similar to high-speed steel, but with more cobalt for improved performance when cutting harder metals such as stainless steel or nickel alloys Titanium Carbonitride(TiCN) allows for optimal end mill and machine tool performance with it's ability to increase material removal rates 3 to 5 times that of uncoated tools Center Cutting End Mills are designed with "End Teeth" making these ideal for applications such as profiling, contour and slotting

Payment

We accept PayPal and credit cards via PayPal.

Taxes - US

We collect sales tax, as required by law.

Shipping

We make every effort of shipping within 3 business day of payment clearing. The estimated delivery time is 2 - 5 business days from the shipping date.

Policies

If you do need to return your item, please contact us via email (you will receive an email when your product ships with additional details - Subject: Important information about your purchase). You will then be provided with a return shipping label and packing slip. Pack the item carefully. Include the packing slip, apply the shipping label, and return the item within 30 business days of the date you request a return, or your return will be canceled. Once we receive your order we will inspect the return. Please allow up to 5 business days of receiving the returned item for your refund.

Added to your wish list!

- Niagara Cutter N67345 Cobalt Steel Ball Nose End Mill, Weldon Shank, Ticn

- 3 in stock

- Price negotiable

- Handling time 3 days.

- Returns/refunds accepted

Get an item reminder

We'll email you a link to your item now and follow up with a single reminder (if you'd like one). That's it! No spam, no hassle.

Already have an account?

Log in and add this item to your wish list.